|

Measurement of temperature coefficient of saturation voltage |

I tested to see how Vec varies with temperature. During my testing, I was running 50 amps of collector current through the IGBT continuously. I was constantly making sure the current was at 50 amps, and it remained at 50 amps for all of my testing. I inserted a thermocouple probe into the heatsink to measure the temperature. I drilled a 2 inch deep hole into the heatsink with a small drill bit. I then covered the thermocouple probe in thermal grease and inserted it in the full 2 inches. So, the tip of the probe was under the IGBT and inside the heatsink. I kept the IGBT on that aluminum block but I didn't run water through the block. So, the heat sink would heat up slowly since there was no water flow.

|

|

Results for the Vec versus temperature test

Ic (amps) |

Heatsink Temperature (Celsius) |

Vec (Volts) |

Notes |

50 |

27 |

1.31 |

|

50 |

36 |

1.30 |

|

50 |

43 |

1.27 |

|

50 |

47 |

1.26 |

|

50 |

51 |

1.25 |

|

50 |

55 |

1.24 |

|

50 |

60 |

1.23 |

Heatsink was almost too hot to touch |

50 |

65 |

1.21 |

|

50 |

68 |

1.2 |

|

50 |

74 |

1.18 |

|

50 |

78 |

1.17 |

Heatsink was too hot to touch |

So as the IGBT heats up it dissipates less power into the heatsink. (Since Vec goes down)

Based on that data the temperature coefficient of saturation voltage for a CM600 is 2.74 mV/°C

Measurement of current sharing between two paralleled CM600's carrying direct current |

For the next round of testing, I decided to see how two IGBT's would share current when they are paralleled. Since the CM600's have a negative temperature coefficient of saturation voltage, runaway effects can occur, where one IGBT begins to carry more and more current as it heats up. One method to combat this problem is to ensure that paralleled IGBT's remain at the same temperature. This can be achieved by mounting both IGBT's near eachother and using large heatsinks or watercooling to minimize any differences in temperature between devices.

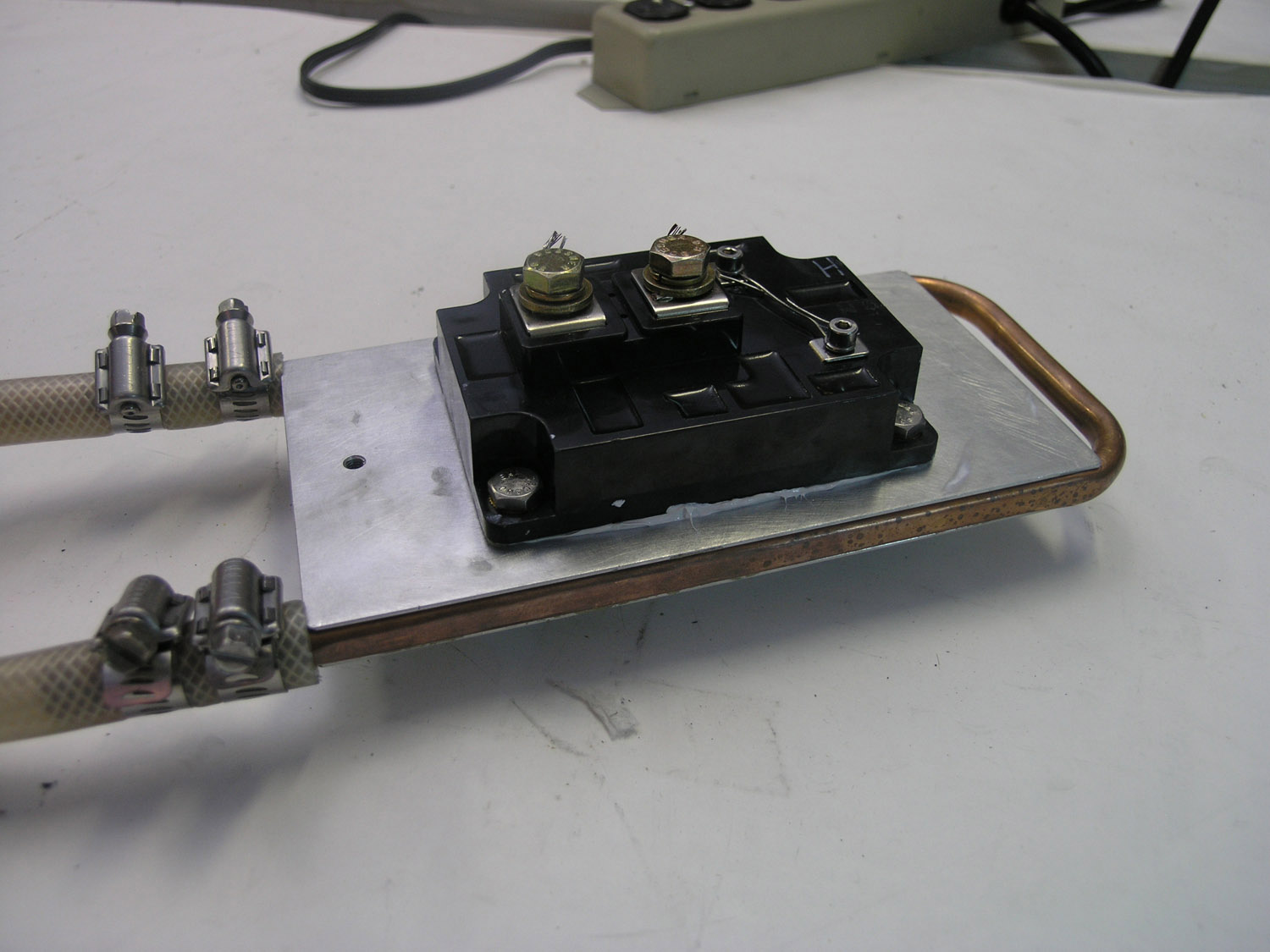

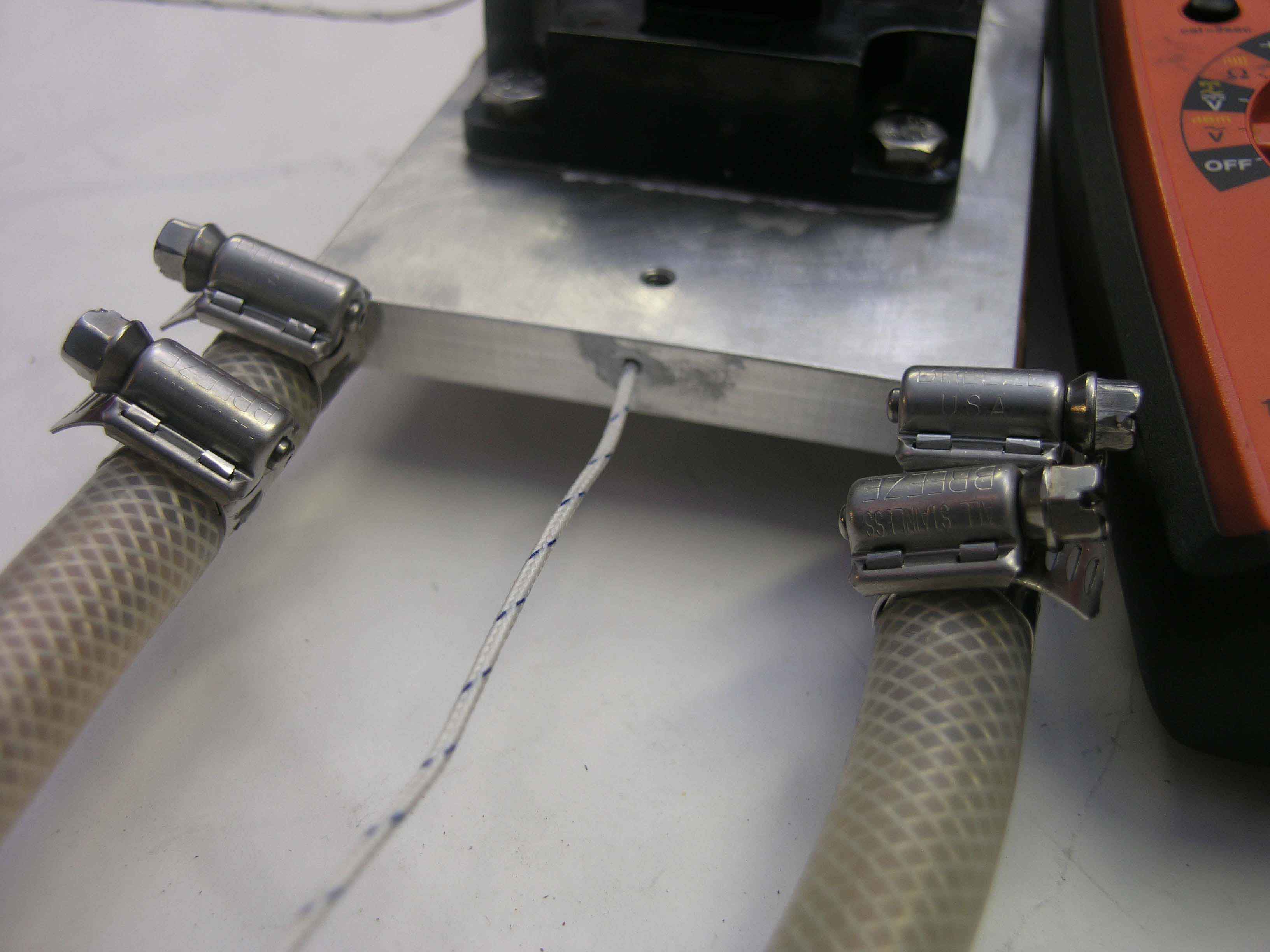

In order to test the claim that extensive cooling will maintain current sharing, I mounted two CM600's right next to eachother on a water cooled copper rail. I then paralleled both of them and ran 80 amps through the circuit. Under ideal circumstances, both of the CM600's should be carrying 40A and 40A. Temperatures for both IGBT's were measured by with a thermocouple probe inside the heatsink right below each IGBT.

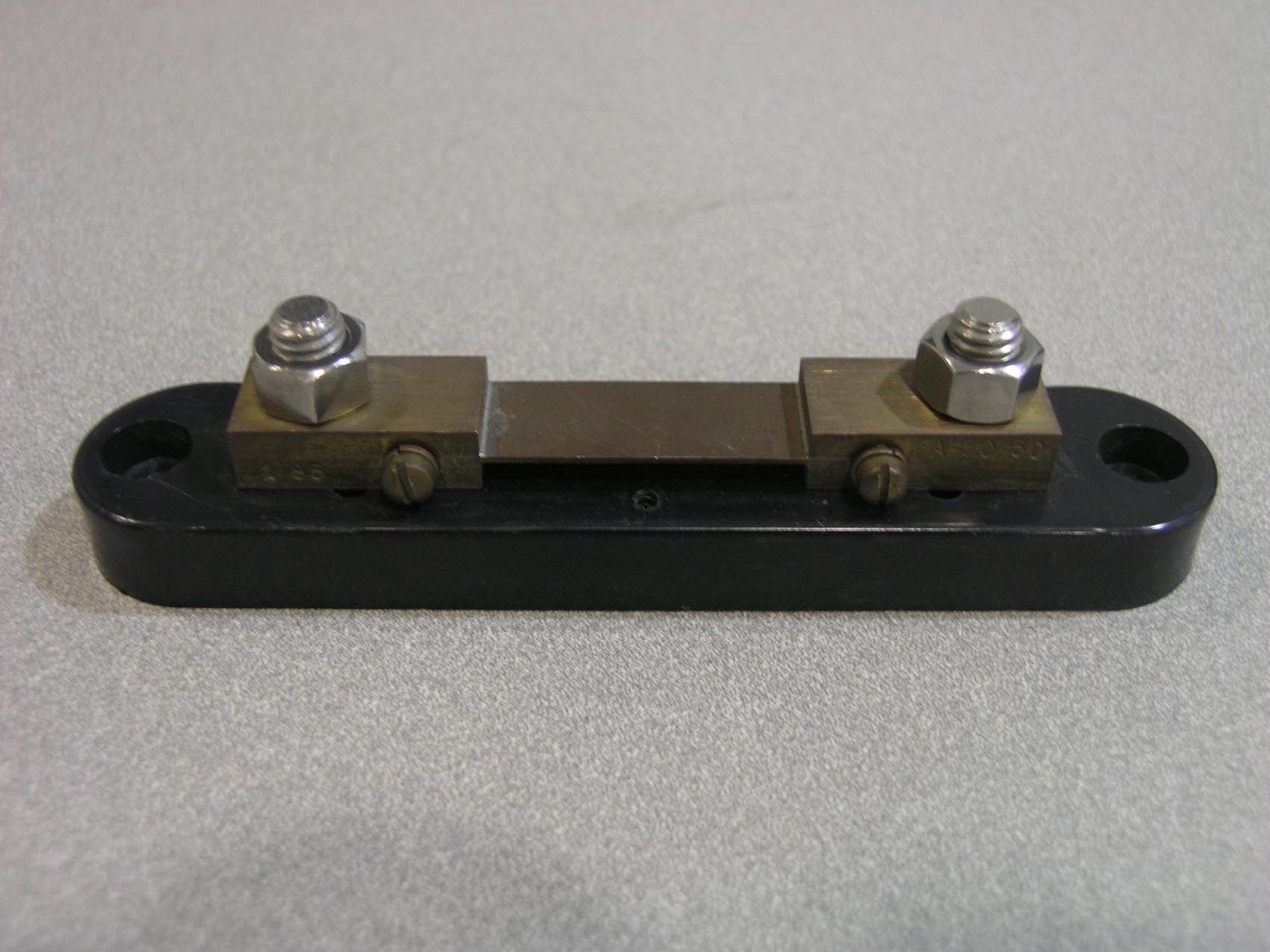

My power supply for this test had an ammeter. I then measured the current through one of the CM600's with a 50A shunt, and the other CM600 current could be obtained from the difference between the ammeter current on the power supply and the current reading from the shunt.

50A shunt I used for measurement.

|

Test results where both IGBT 1 and IGBT 2 are adequately cooled and at the same temperature.

Temperature of IGBT 1 (Celsius) |

Temperature of IGBT 2 (Celsius) |

Current Through IGBT 1 (Amps) |

Current Through IGBT 2 (Amps) |

Time (minutes) |

31 |

31 |

40 |

40 |

2 |

33 |

33 |

40 |

40 |

4 |

35 |

35 |

40 |

40 |

6 |

36 |

36 |

40 |

40 |

8 |

37 |

37 |

40 |

40 |

10 |

37 |

37 |

40 |

40 |

12 |

37 |

37 |

40 |

40 |

14 |

37 |

37 |

40 |

40 |

16 |

37 |

37 |

40 |

40 |

18 |

So, paralleling large IGBT's seems to work fine as long as their temperatures are close to eachother.

For the next test, one IGBT was removed from the water cooled rail and placed on a very small heatsink. The purpose of this test was to create a situation where on IGBT has adequate cooling and the other does not. This will create a large temperature difference between the IGBT's and in theory one will start to conduct much more than the other.

Test results where only IGBT 2 is adequately cooled

Temperature of IGBT 1 (Celsius) |

Temperature of IGBT 2 (Celsius) |

Current Through IGBT 1 (Amps) |

Current Through IGBT 2 (Amps) |

Time (minutes) |

Notes |

27 |

27 |

40 |

40 |

4 |

|

34 |

29 |

40 |

40 |

8 |

|

37 |

30 |

40 |

40 |

12 |

|

46 |

31 |

41 |

39 |

16 |

|

54 |

31 |

42 |

38 |

20 |

|

61 |

31 |

42 |

38 |

24 |

|

64 |

31 |

43 |

37 |

28 |

|

67 |

31 |

44 |

36 |

32 |

|

70 |

31 |

45 |

35 |

36 |

|

76 |

31 |

47 |

33 |

40 |

The small heatsink for IGBT 1 is way too hot to touch |

So the runaway effect occurred! As IGBT 1 became hot, it started to carry more and more current.

Miscellaneous Testing |

I put about 30 milliamps of current through the IGBT. The Voltage drop from Emitter to Collector was .5 volts.

So even at very low Collector currents, there is still a fair amount of voltage drop across E and C.

For the next test, I had the gate at zero volts. I then put 500 Volts across the Collector and Emitter. I wanted to see what the leakage current was. It turns out there was virtually no leakage current at all. My milliamp meter didn't read anything, so the leakage current was likely something in the microamp range, or perhaps even less.

Next, I did a series of voltage drop testing across the Emitter and Collector for some given collector current.

Here are those results (Ic denotes The current through the IGBT and Vec is the voltage drop across the IGBT)